|

Ducati Clutch Basics

by Larry "Shazaam!" Kelly

The Ducati dry clutch is famous for it’s unique noise that makes it desireable to some but an annoyance to others. The reason that they’re noisy is that each time you shift, the edges of the friction plates hammer the fingers of the clutch basket, causing each to deform, and making the gap between them to get larger, causing higher impact forces (the next time), and so on, causing a louder rattling noise each time the clutch is disengaged. So, they get louder and louder until the plates and basket are replaced.

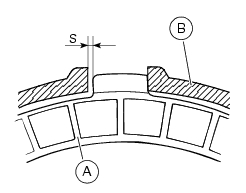

Clutch Plate (A) to Clutch Basket (B) Clearance Guide.

The gap (S) should be less than 0.6mm, but this doesn't

mean the clutch is worn out! It will just rattle more...

The noise doesn’t necessarily mean that your clutch is worn out. A clutch is considered worn out when the thickness of the friction material on one or more friction plates exceeds the minimum allowable. It’s recommended that you replace a 3mm (new) friction plate when it reaches it’s service limit of 2.8mm, and replace a 2.5mm friction plate when it reaches 2.3mm.

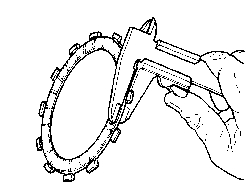

Measuring the thickness of a Clutch (Friction) Plate.

Measure the thickness of the plate across the friction material.

Replace the plate when it wears by 0.2mm.

When the plates wear, the plate stack height is reduced so when the stack height wears 0.5mm, you can replace one flat steel plate with a one 0.5mm thicker to recover the correct stack height. At 1.0mm wear repeat for a second flat plate. At 1.4mm wear you’ll want to replace the friction plates. This is the time to replace the basket if you want to quiet your clutch.

Ducati Clutches need to be stacked to 38mm plus (+) or minus (-) 2mm.* The reason that maintaining the overall stack height is important is that the force pushing the plates together comes from the preload of the clutch springs. The higher the stack height, the higher the preload. Also for a given stack height, the more springs the higher the force pushing the plates together. Not enough spring preload, not enough springs, or not enough friction material and your clutch will slip.

The standard test for a slipping clutch is to check while accelerating in top gear.

Quiet Clutch Mod

It's been sugested that adding a plate at the bottom of the stack will reduce clutch noise. This plate is not an addition to the existing stack; the stack height has to be maintained. This is a rearrangement of plates in the stack.

The idea here is to move the friction plates to a new location in the stack so that they no longer are alligned with the notches in the basket (notches that they caused previously.) This in turn reduces the tab-to basket clearances for the friction plates so you get less noise.

A badly worn (notched) clutch basket - this needs replacing!

The arrangement of plates in the stack, the number of plates, and the thickness of plates vary from model to model, but the one feature that all arrangents have in common is stack height. Here’s some examples:

748, 916, 996 (From the Haynes Manual)

7 friction plates, 1 convex plate (marked with a dot on the inner edge) in the following order:

2.0mm flat plate

2.0mm* flat plate

3.0mm friction plate

1.5mm convex plate (convex side facing outwards)

3.0mm friction plate

2.0mm* flat plate

3.0mm friction plate

2.0mm flat plate

3.0mm friction plate

2.0mm* flat plate

3.0mm friction plate

2.0mm flat plate

3.0mm friction plate

2.0mm flat plate

3.0mm friction plate

2.0mm flat plate

pressure plate (line up marks)

38.5mm Total

916SP, 916SPS, 996S, 996SPS

8 (thinner) friction plates in the following order:

2 convex plates

2.0mm flat plate

1.5mm convex plate (convex side facing outwards)

2.5mm friction plate

1.5mm* flat plate

2.5mm friction plate

2.0mm flat plate

2.5mm friction plate

2.0mm* flat plate

2.5mm friction plate

2.0mm flat plate

2.5mm friction plate

2.0mm* flat plate

2.5mm friction plate

2.0mm flat plate

2.5mm friction plate

1.5mm flat plate

2.5mm friction plate

1.5mm convex plate (convex side facing inwards)

pressure plate (line up marks)

38mm Total

998 (From the Ducati Service Manual)

6 friction plates in the following order:

1 convex plate

2.0mm flat plate

1.5mm convex plate (convex side facing outwards)

2.5mm* flat plate

1.5mm flat plate

3.0mm friction plate

2.0mm* flat plate

3.0mm friction plate

2.0mm* flat plate

3.0mm friction plate

2.0mm flat plate

3.0mm friction plate

2.0mm* flat plate

3.0mm friction plate

2.0mm flat plate

3.0mm friction plate

1.5mm flat plate

2.5mm* flat plate

1.5mm convex plate (convex side facing outwards)

pressure plate (line up marks)

38mm Total

Of course shifting the plates around to reduce plate-to-basket clearances is only a temporary fix until the plates hammer-out new and bigger clearances.

More Lasting Solutions

There has been some innovation to try to address the durability issue associated with the plates impacting and notching the basket.

For example, STM and Sigma (UK) has tried to overcome this problem by increasing the number of tabs on each plate (and the number of basket fingers) from the stock 12 to 48 tabs. The intended result is to distribute the impact loads over a larger tab-basket contact area (lower psi) to reduce notching to the clutch basket fingers and mushrooming of the plate tabs. Only STM and Sigma offer a 48-tab clutch pack, however.

Nichols Manufacturing designed their CNC-machined aluminum basket with wider basket fingers that results in larger finger contact area and consequently lower impact stresses, particularly when combined with their Barnett aluminum clutch pack where extra care has been taken to initially minimize gaps. Another option is a Barnett aluminum basket with stainless steel inserts to protect the basket fingers.

Keep in mind that when you mix steel and aluminum, the softer metal deforms preferentially and clearance gaps suffer, more than for steel-to-steel. So if you have a steel basket, stick with steel plates.

|